Myth #1: Autonomous technology is immature and unsafe

Fact: The current maturity level in autonomous driving is the result of decades of development and preparation -- with safety always being the highest principle.

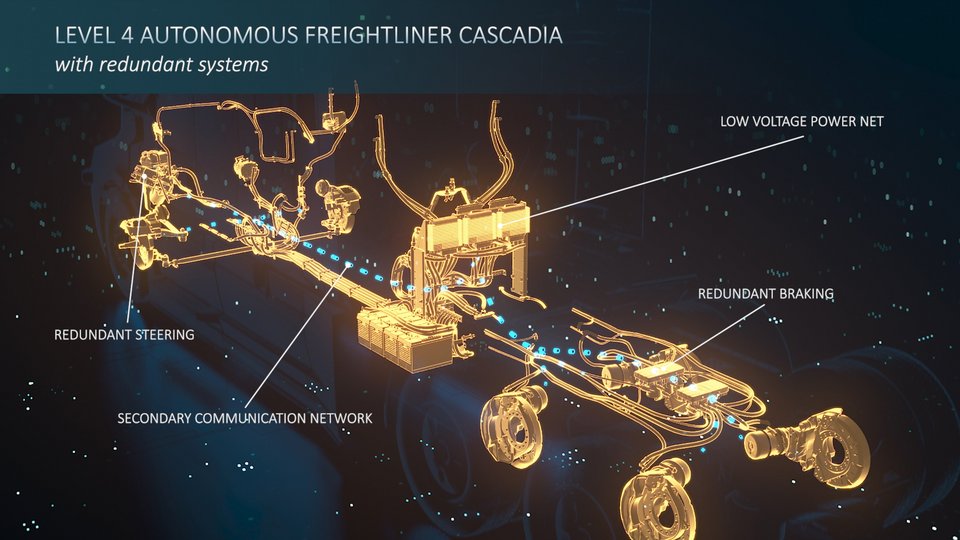

When it comes to autonomous driving, we leave nothing to chance. Our engineers carefully and accurately check every detail, to create a safe product wherever possible – this includes extensive test track testing and simulation as well as on road validation. Work on autonomous vehicles at Daimler Truck goes back to the 1980s. Since 2019, we have made significant progress together with our partner Torc Robotics to make the idea of autonomous trucks a reality. We have shown that our self-driving trucks can safely handle challenging traffic situations – highways, surface streets, ramps, and turns at controlled intersections. The core of our technology development is our “redundant vehicle platform”, the "Autonomous-Ready" Freightliner Cascadia as the basis for safe driving, as well as the autonomous driving software, the “Virtual Driver” from Torc. Our vehicle platform is purposefully designed and built with a second set of safety-critical systems such as steering, braking and the power network as a backup, assuring that if one fails, the other immediately takes over. The highly integrated autonomous driving software "sees" (camera, radar, LiDAR detection) by perceiving the environment near and far ahead, “thinks” (plans the next maneuver) and “acts” (lane changes, acceleration, braking, merging). The Autonomous Driver thereby remains at a very high-performance level – and technical systems never get tired, cannot be distracted and are not guided by emotions.

Bottom line: We have achieved a lot on the path towards the self-driving truck, but there is more testing and development work ahead before we enter the U.S. market. In that respect, the principle of safety defines the timeline.