Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Download

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Gaggenau / Kassel – Mercedes-Benz Trucks will celebrate the start of series production of the eActros 600 at the end of November this year at the Mercedes-Benz plant in Wörth. The eActros 600 was recently selected as “International Truck of the Year 2025” at the IAA-Transportation in Hannover. The first eActros 600 customer vehicles will be manufactured and registered before the end of 2024. Key components from the…

Gaggenau / Kassel – Mercedes-Benz Trucks will celebrate the start of series production of the eActros 600 at the end of November this year at the Mercedes-Benz plant in Wörth. The eActros 600 was recently selected as “International Truck of the Year 2025” at the IAA-Transportation in Hannover. The first eActros 600 customer vehicles will be manufactured and registered before the end of 2024. Key components from the Mercedes-Benz plants in Gaggenau and Kassel will be installed in each vehicle.

Key components come from Gaggenau

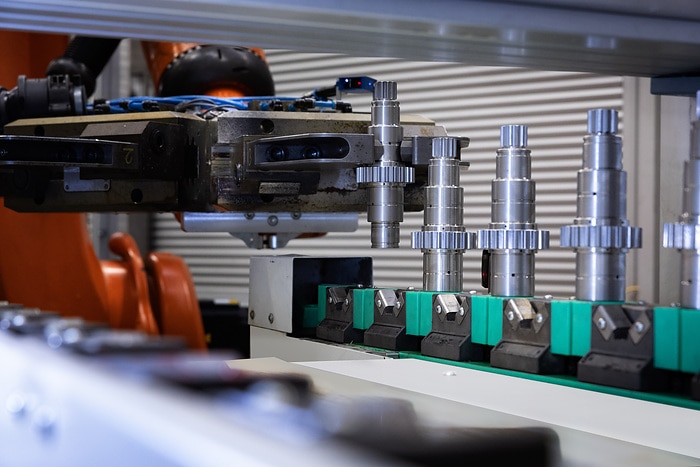

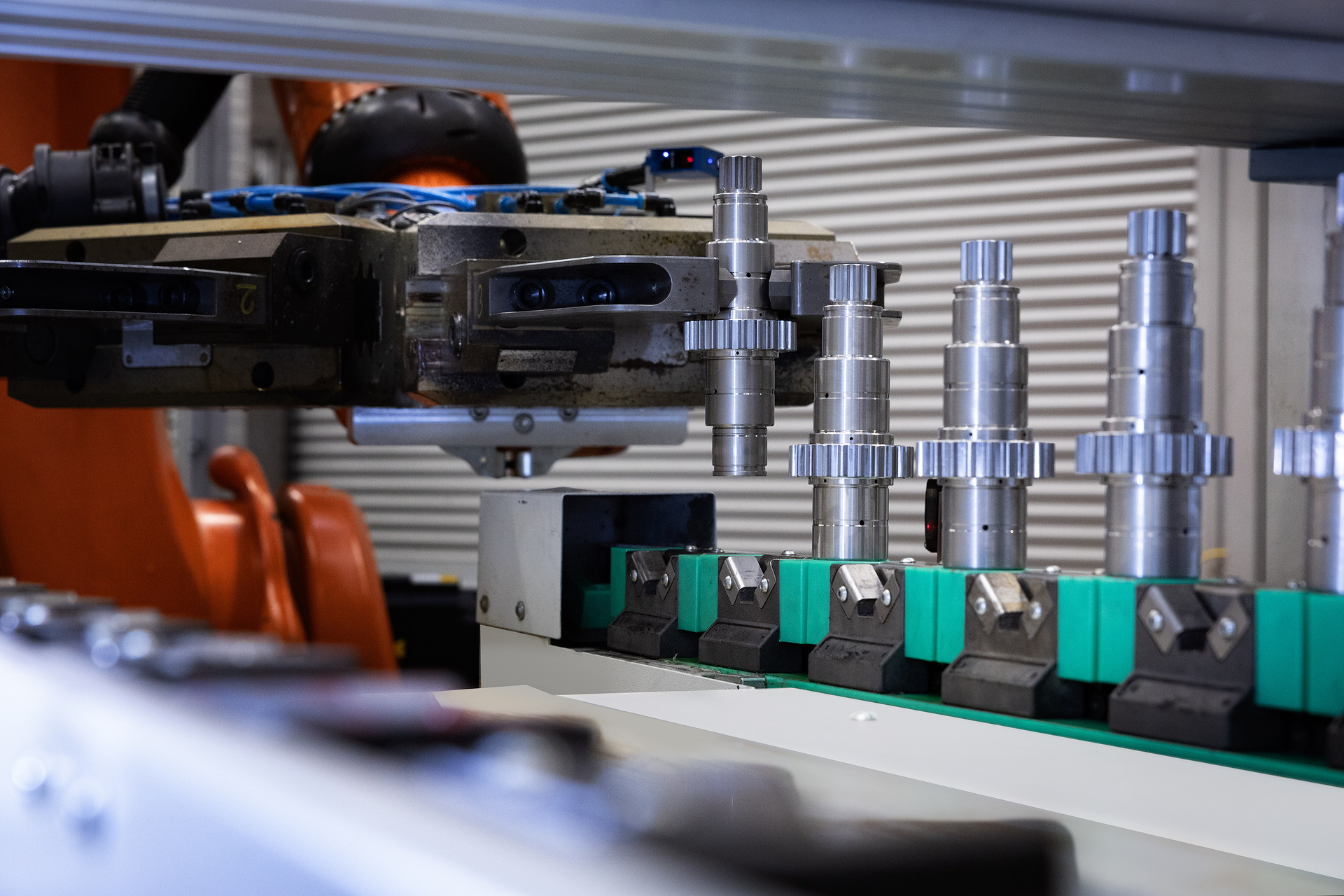

The Mercedes-Benz plant in Gaggenau, which specializes in transmissions for heavy-duty commercial vehicles, is currently developing into a center of expertise for electric drive components. Since 2021, key parts for the e-axle (a unit that combines the axle, motor and transmission and represents the electric powertrain) of the eActros 300/400 for distribution transport and the eEconic have been manufactured in Gaggenau. The same will apply to the central components of the new generation of the electric axle that will power the eActros 600. These are mechanical parts of the kind that Gaggenau has been producing for vehicles with conventional drivelines for many years. They are used to make the state-of-the-art, innovative 4-speed axle drive, which contains a total of around 30 different components. These include specially developed transmission components such as shafts, gears and synchronizer parts, as well as housing parts. Gaggenau supplies these components to Kassel, where the complete assembly of the axle and transmission components takes place and the newly developed, electrically driven rear axle is created.

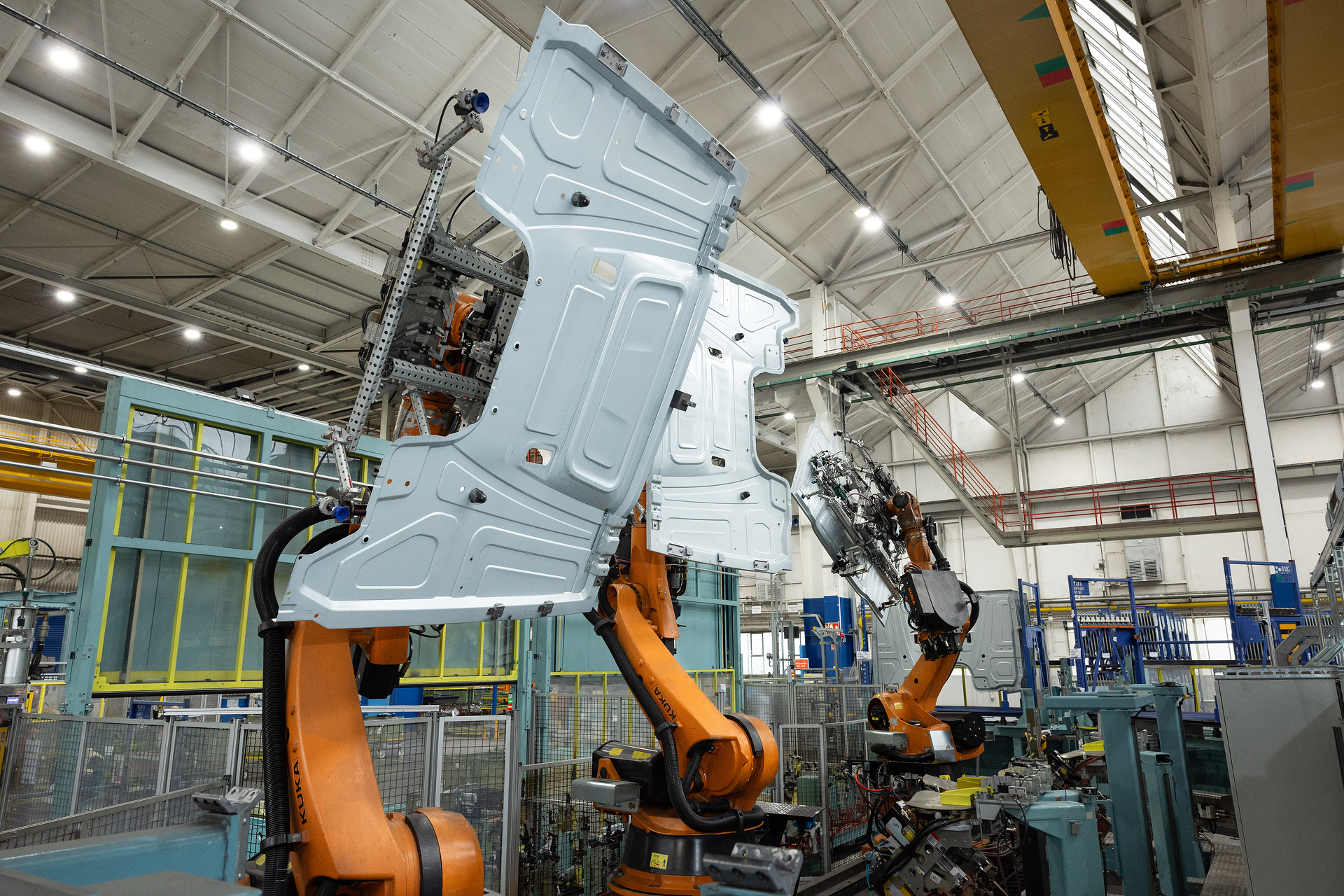

In addition, the bodyshell components for the cab of the eActros 600 are also manufactured in Gaggenau. The scope of supply includes, among other things, structural body parts such as the rear panel, roof frame, bulkhead and cross members, as well as various reinforcements. These are carry-over parts that are already used in conventionally powered trucks. The bodyshell expertise of the plant thus “carries” the outer skin of the newly designed cab of the new battery-electric long-haul truck.

All elements of the electric powertrain are subject to stringent requirements in terms of quality, service life and installation space. For example, the geometric specifications for surfaces and roughness of the gearing of gears and shafts only allow for very narrow tolerances. The latest and highly precise manufacturing technologies, such as specialized gear grinding machines, make it possible to guarantee the required quality.

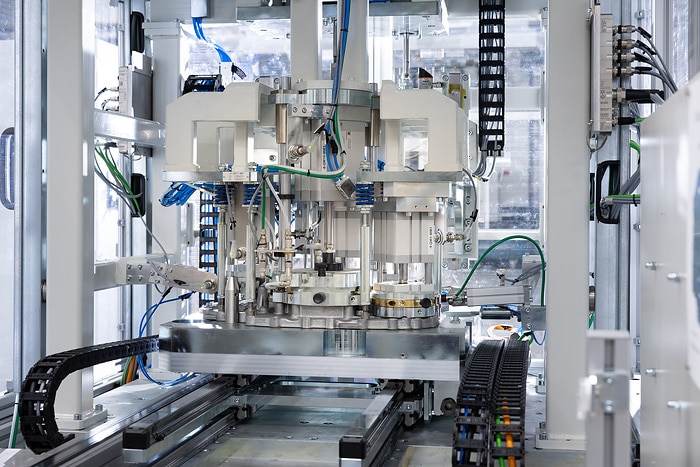

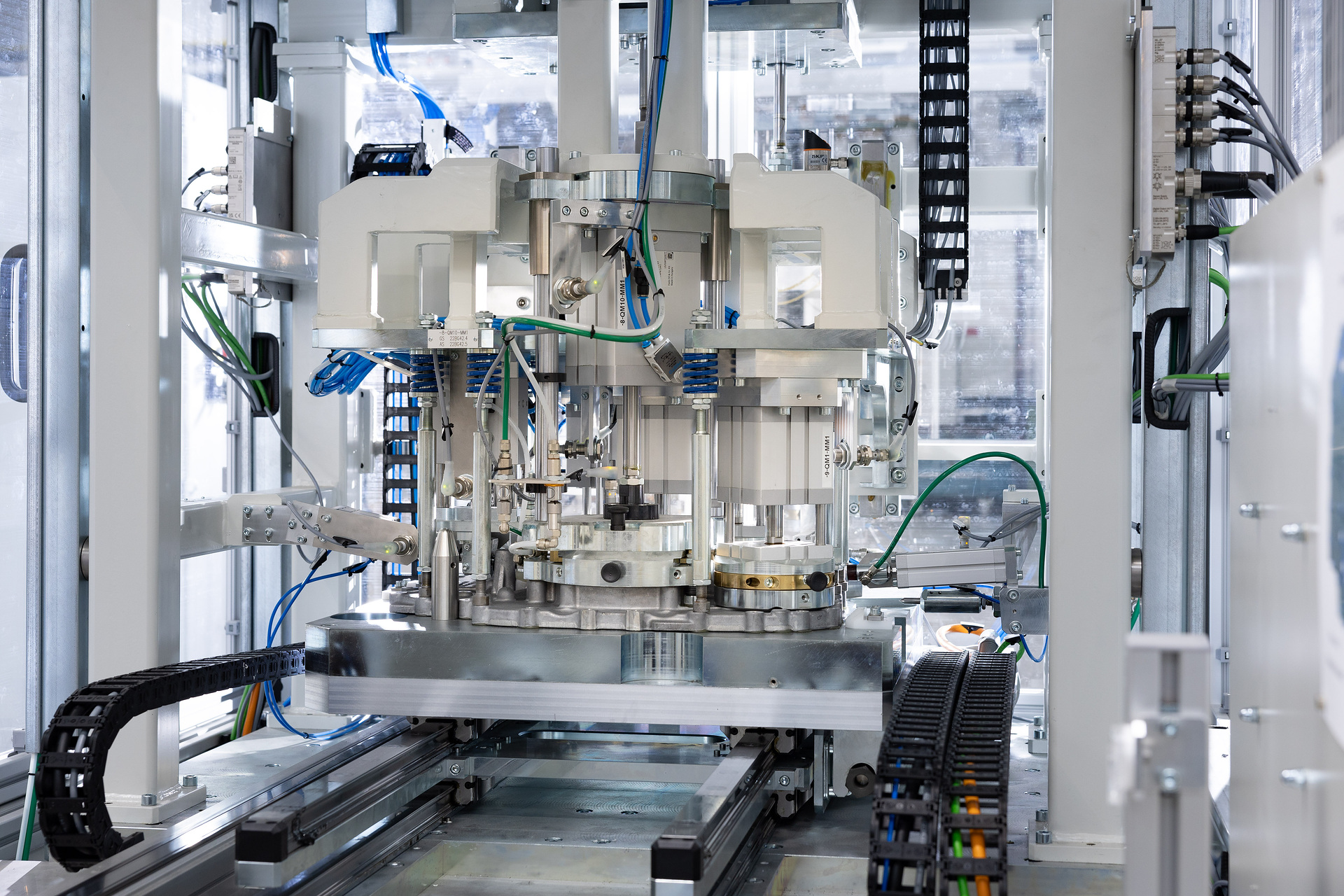

The mechanical processing of the housing parts takes place in a specially converted hall at the Gaggenau factory. A completely new production plant with automated processing centers has been set up here. During the procurement phase, the virtual commissioning of these centers enabled the processing to be simulated on so-called “digital twins”. This process results in enormous time savings compared to a conventional production plant setup process. The mechanical processing includes drilling and milling, as well as thread cutting, before the housings undergo a leak test.

Thomas Twork, Plant Manager Mercedes-Benz Plant Gaggenau: “No future without the past! At the Mercedes-Benz plant in Gaggenau, tradition and transformation go hand in hand. We are proud to apply our decades of experience in the manufacture of high-precision transmission components to the new electric powertrain. Together with our colleagues at the assembly plant in Kassel, our plant is making an important contribution to emission-free mobility”.

Michael Brecht, Chairman of the Group Works Council of Daimler Truck and Chairman of the Mercedes-Benz Plant Gaggenau Works Council: “In particular, the production volumes for the e-axle represent a production network with the Kassel plant. Together, we are making a significant contribution to the new electric powertrain. This is how we generate innovations and also provide orientation for the workforce, so that we can tackle the new technology topics.”

The newly developed e-axle is being developed in Kassel

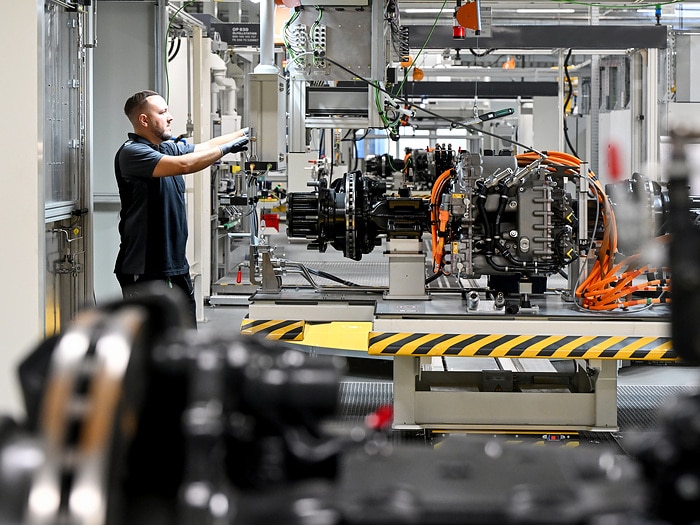

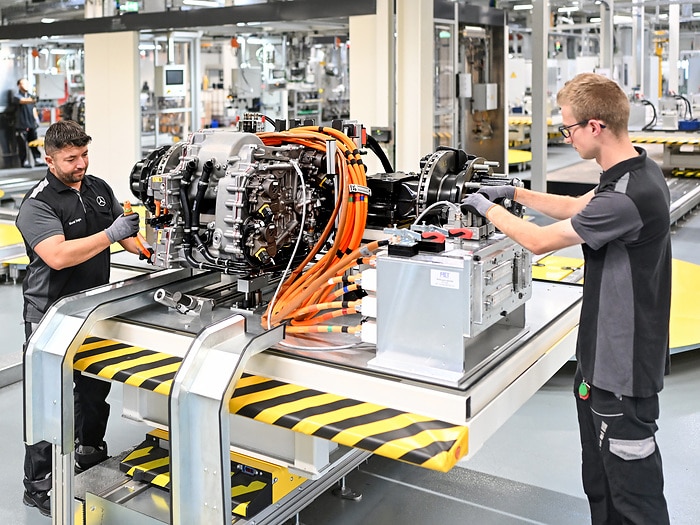

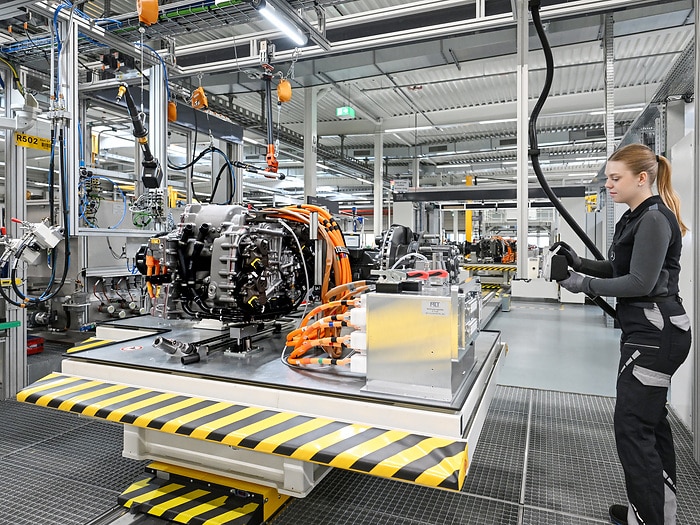

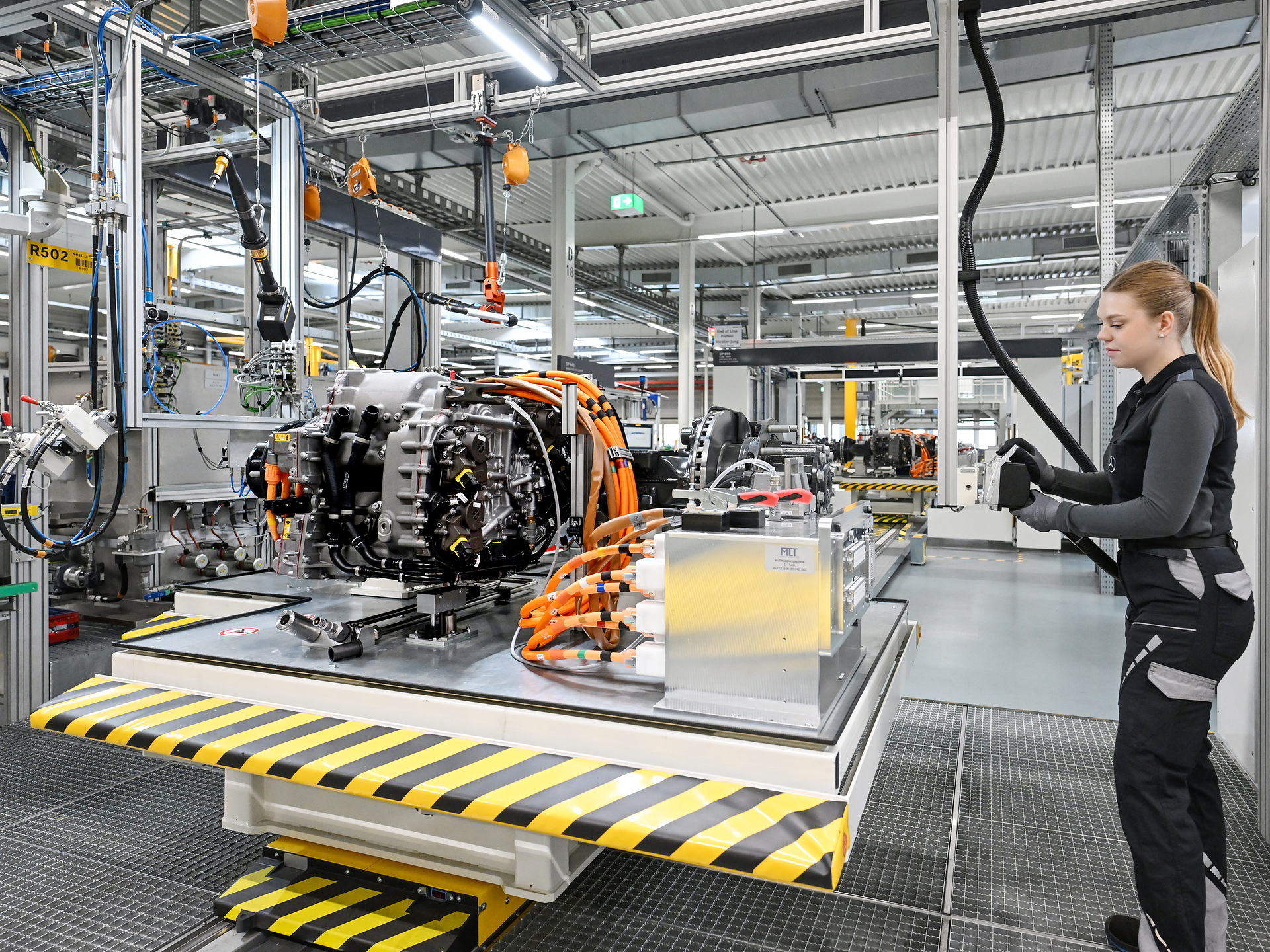

The Mercedes-Benz plant in Kassel, the global center of excellence for conventional axles and electric drive systems, is assembling the new generation of the e-axle for the eActros 600. The electrically driven rear axle has been redesigned specifically for long-distance transport. It features a range of technical innovations for higher performance and efficiency.

A new assembly line has been built at the plant for this purpose, including test and inspection stations for the functional and safety-related features. Just as for the e-axle, which is currently used in the eActros 300/400 and eEconic, and which is already manufactured in Kassel, the “common parts principle” also applies to the new generation. This means that the body axle as well as the wheel end and brake components originate from the conventional axle, which the Kassel plant has been manufacturing for over two decades. The components are produced in a highly flexible manner on the assembly line, so that the plant can vary between conventional and electric axles depending on the order situation.

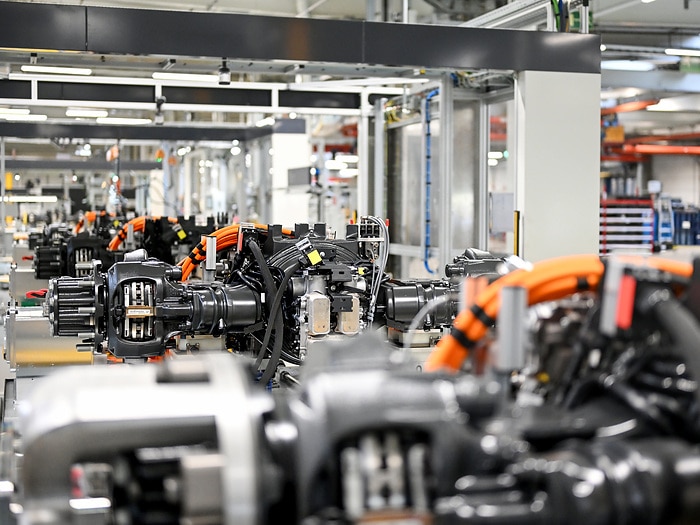

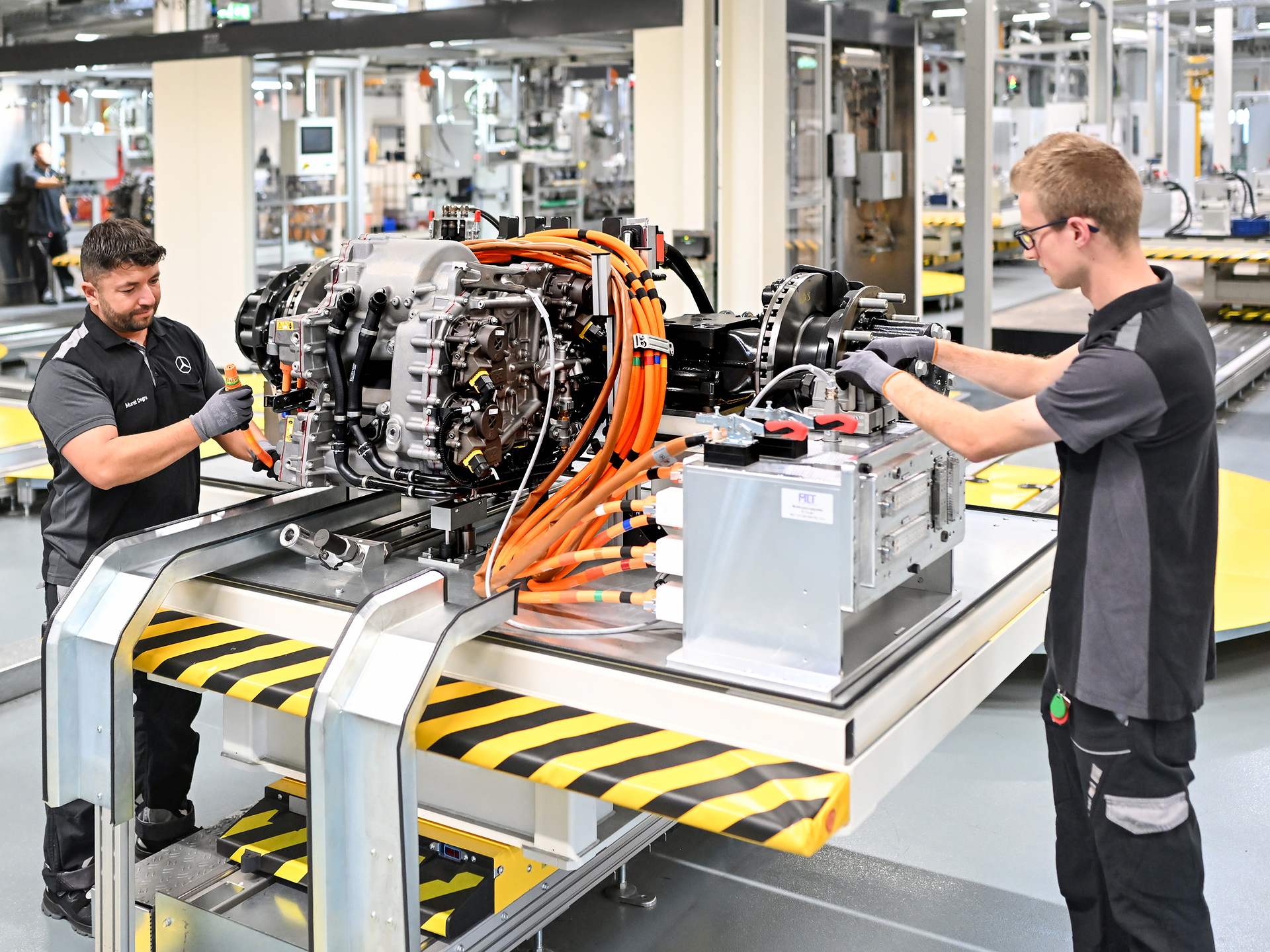

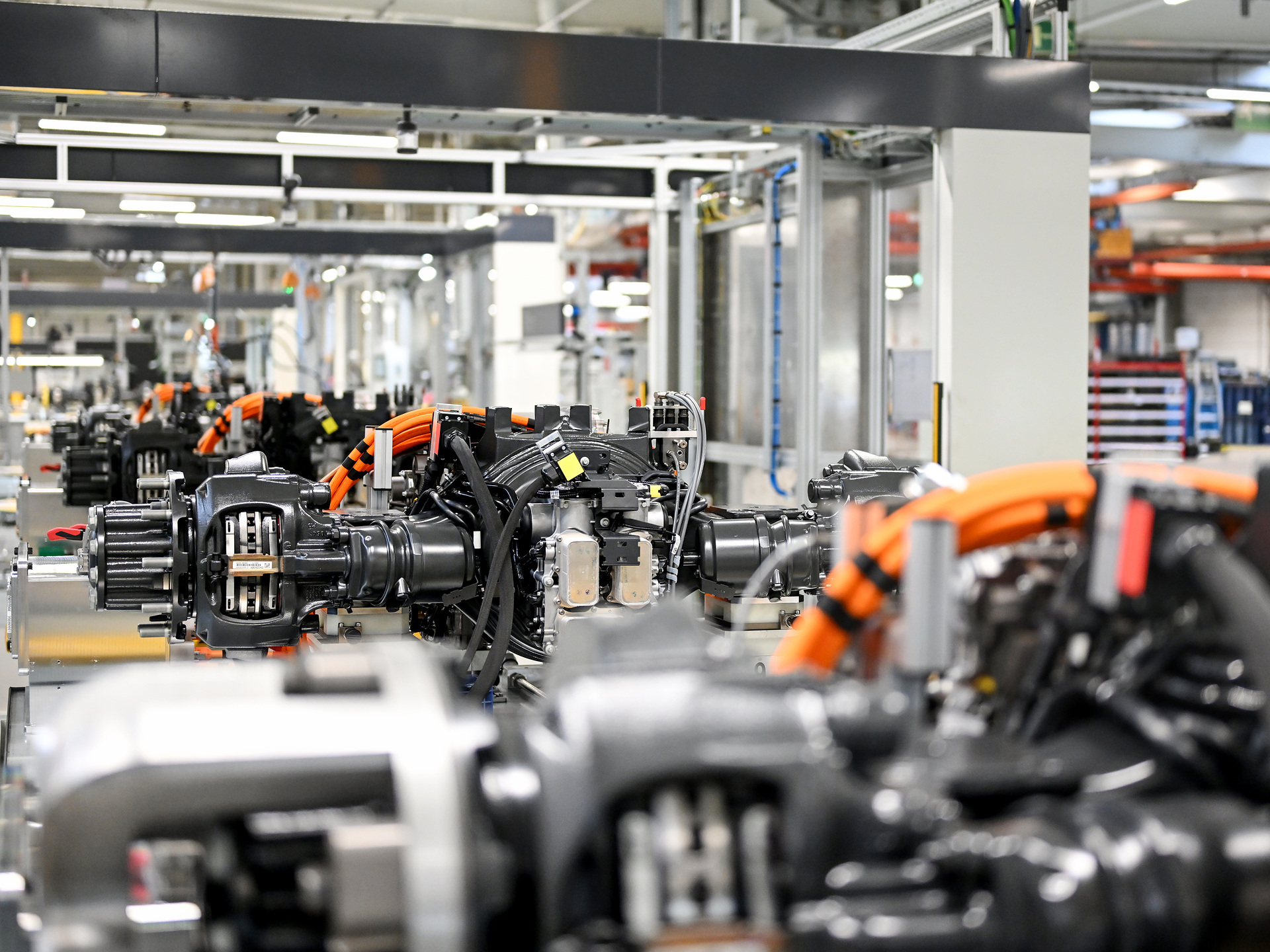

The new generation of the E-axle consists of the axle arch and an electric drive system comprising electric motors as well as the transmission and high-voltage components.

Assembly process of the new generation of the E-axle in Kassel

The holistic assembly process at the Kassel plant takes place in various coordinated phases. The axle carrier forms the basis for the new e-axle and is prepared for the suspension, rolling and braking in the first step – i.e. wheel hubs, drive shafts and brake drums are mounted here. The axle carrier for the e-axle is the same as for the conventional series, so it can be easily adapted to the existing vehicle chassis.

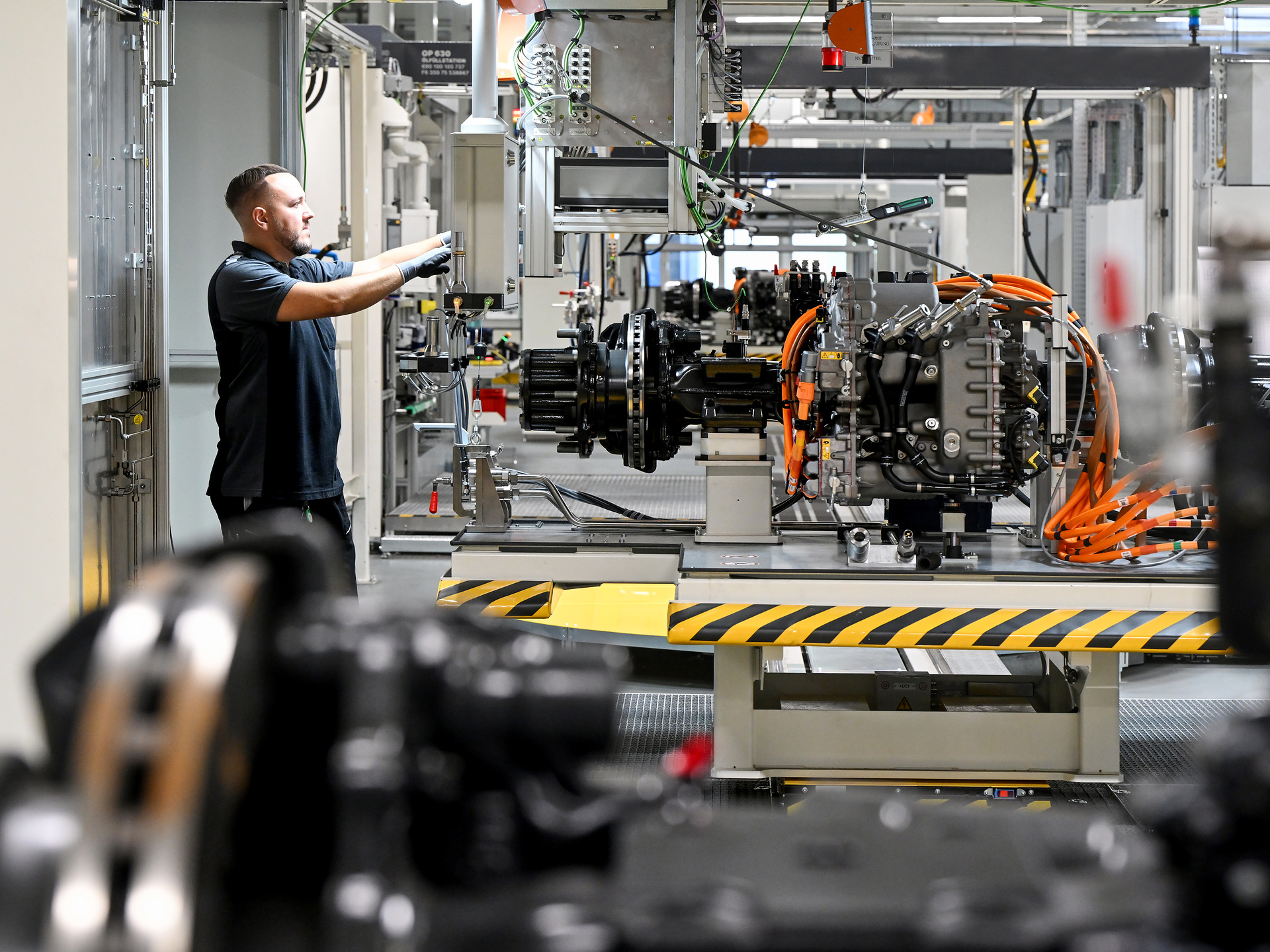

In the assembly area of the electric drive unit, the pre-assembled transmission parts, the two electric motors and other components are installed in the axle carrier housing, which comes from Gaggenau. In the final assembly, the so-called marriage between the previously created electric drive unit and the axle bridge takes place. Furthermore, various sensors, oil and cooling lines as well as low-voltage cable sets are installed without electricity.

Before the electric axle leaves the Mercedes-Benz plant in Kassel, it undergoes a detailed functional test of the mechanical and electrical components, the so-called “end-of-line test” (EOL test), in the last phase. This is where the high-voltage cables are installed, the leak test is carried out and the high-voltage tests are performed. Finally, the electric axle is subjected to a simulation of various driving situations, including load, topography and gear selection profiles. After passing the EOL test, the e-axle is prepared for transport to the Mercedes-Benz plant in Wörth.

Hauke Schuler, Plant Manager of Mercedes-Benz Plant Kassel: “We are proud that we now also have an e-axle for CO2-neutral long-distance transport in our product portfolio. With its unique and efficient design, which integrates the electric drive into the existing axle concept, it contributes to the long range of the eActros 600. This is another important milestone for the Mercedes-Benz plant in Kassel in the transformation to emission-free mobility.”

Jörg Lorz, Deputy Chairman of the General Works Council of Daimler Truck and Chairman of the Mercedes-Benz Kassel Works Council: “Our team at the Mercedes-Benz Kassel plant is passionate about the production of the new E-axle. We are thus making a significant contribution to the success of this innovative new drive technology at Daimler Truck. Both stand for the joint production and technology network with the Gaggenau plant.”

About the Mercedes-Benz plants in Gaggenau and Kassel

The Mercedes-Benz plant in Gaggenau was founded in 1894 as "Firma Bergmann's Industriewerke in Gaggenau" and is the oldest automotive plant in the world. In addition to transmissions, the site produces planetary and portal axles as well as passenger car components, including torque converters. The Mercedes-Benz plant in Gaggenau is currently developing into a competence center for electric drive components and the assembly of hydrogen-based fuel cell units. Together with Gehring Technologies GmbH, the site wants to drive forward the prototypical construction of so-called "truck-e-fied" e-engines as well as the further development and testing of innovative production processes. With its approximately 4,600 employees, it is both the city's largest employer and the region's largest training company. Vocational training also has a long tradition: for over 100 years, more than 10,000 young people have completed their training at the oldest automotive plant.

At the Mercedes-Benz plant in Kassel, experience in truck manufacturing goes back to 1925. The Mercedes-Benz plant in Kassel was founded in 1969 as “Hanomag-Henschel-Fahrzeugwerke GmbH” and hast been manufacturing axles for commercial vehicles, among other things, for over 55 years. It is Daimler Truck’s global competence center for electric drive systems and conventional commercial vehicle axles. The associated Technology Center for e-drive systems at the site is actively shaping the future of locally CO2-neutral vehicles. In pioneering production processes, the approximately 2,700 employees manufacture axles for trucks, buses, vans and passenger cars, as well as cardan shafts and gear sets, among others. For climate-friendly and future-oriented production, the plant has, among other things, a complete hall with two assembly lines in operation that draws all its energy from photovoltaic systems on the roof of the hall. In addition, the plant works closely with the University of Kassel in scientific projects on strategies relating to the topics of sustainability and mobility of the future. The Kassel plant is one of the largest commercial vehicle axle plants in Europe and the largest industrial employer in the city.

Article assets

Start of production of key components for series production of the battery-electric Mercedes-Benz eActros 600

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Start of production of key components for series production of the battery-electric Mercedes-Benz eActros 600

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Start of production of key components for series production of the battery-electric Mercedes-Benz eActros 600

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Production start for central components of the new eActros 600 at the Gaggenau and Kassel plants

Arnd Minne

Spokesperson Corporate Communications Mercedes-Benz Trucks & Daimler Buses

arnd.minne@daimlertruck.com

+49 176 30912514

Dorothea Freiberg

Spokesperson Mercedes-Benz Trucks Plants Gaggenau, Kassel and Mannheim

dorothea.freiberg@daimlertruck.com

+49 160 8669616