Customization on wheels – Mercedes-Benz Custom Tailored Trucks celebrates its 25th anniversary

Download

Customization on wheels – Mercedes-Benz Custom Tailored Trucks celebrates its 25th anniversary

The Mercedes-Benz Custom Tailored Trucks (CTT) partner network has specialized in customized truck conversions since 2000. Customized production by CTT at its plants in Molsheim (France) and Wörth am Rhein, supplemented by seven specialized partner companies in Germany. CTT offers tailor-made individual solutions in close consultation with customers and rapid implementation thanks to synergies within the partner network. …

- The Mercedes-Benz Custom Tailored Trucks (CTT) partner network has specialized in customized truck conversions since 2000.

- Customized production by CTT at its plants in Molsheim (France) and Wörth am Rhein, supplemented by seven specialized partner companies in Germany.

- CTT offers tailor-made individual solutions in close consultation with customers and rapid implementation thanks to synergies within the partner network.

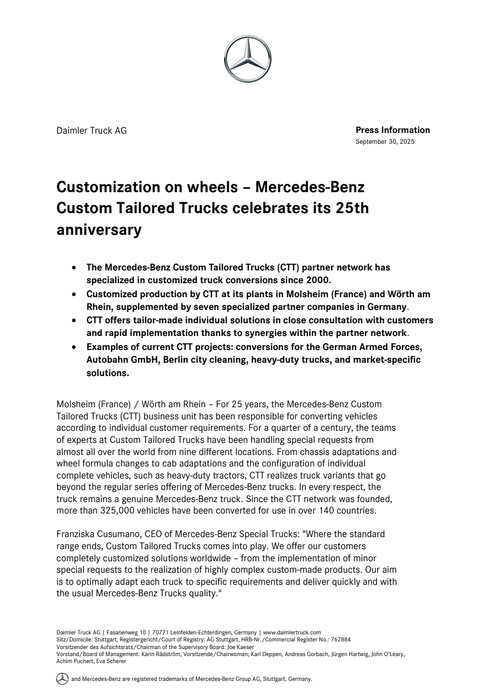

- Examples of current CTT projects: conversions for the German Armed Forces, Autobahn GmbH, Berlin city cleaning, heavy-duty trucks, and market-specific solutions.

Molsheim (France) / Wörth am Rhein – For 25 years, the Mercedes-Benz Custom Tailored Trucks (CTT) business unit has been responsible for converting vehicles according to individual customer requirements. For a quarter of a century, the teams of experts at Custom Tailored Trucks have been handling special requests from almost all over the world from nine different locations. From chassis adaptations and wheel formula changes to cab adaptations and the configuration of individual complete vehicles, such as heavy-duty tractors, CTT realizes truck variants that go beyond the regular series offering of Mercedes-Benz trucks. In every respect, the truck remains a genuine Mercedes-Benz truck. Since the CTT network was founded, more than 325,000 vehicles have been converted for use in over 140 countries.

Franziska Cusumano, CEO of Mercedes-Benz Special Trucks: "Where the standard range ends, Custom Tailored Trucks comes into play. We offer our customers completely customized solutions worldwide – from the implementation of minor special requests to the realization of highly complex custom-made products. Our aim is to optimally adapt each truck to specific requirements and deliver quickly and with the usual Mercedes-Benz Trucks quality."

Marc Schulz, Head of Custom Tailored Trucks: "In an increasingly complex world, the special needs of our customers are also growing. We support them in this and, with Custom Tailored Trucks, we are able to find tailor-made answers to almost all requests. These projects are mainly carried out by our conversion experts at the Molsheim plant, but also in Wörth am Rhein and by our CTT partners throughout Germany. Close coordination with the customer is always our top priority."

A strong network for special requests from around the world

Custom Tailored Trucks (CTT) is a network of expert teams at the two Mercedes-Benz Trucks locations in Molsheim (France) and Wörth am Rhein, supplemented by seven industry partners. Thanks to the division of labor in production at several locations, the special core competencies of the Mercedes-Benz truck plants and the CTT partners can be optimally combined to efficiently implement individual customer requests. For customers, this has a positive effect on delivery speed.

With around 600 employees, the plant in Molsheim near the German-French border, just 100 km from the largest Mercedes-Benz Trucks plant in Wörth, specializes in the conversion of trucks and is the headquarters of the Mercedes-Benz Custom Tailored Trucks business organization. The CTT team at the Molsheim plant delivers tailor-made engineering expertise with a total of 63 conversion stations. Founded in 1967, the site has been converting trucks since 1991. In 2000, the CTT business unit was established within the Daimler Truck organization. This enabled specialized teams to simplify processes and establish a strong partner network. In addition to this core activity, the Molsheim site is also home to the production of Unimog cabs and parts for series-production trucks.

In addition to the conversions in Molsheim, the CTT business unit also implements special customer requests in terms of configuration, function, and truck technology outside the series program at the truck plant in Wörth and in a network of specialized partner companies. The partner companies in the CTT network include S&G Automobil AG, F&B Nutzfahrzeug-Technik GmbH, Werner Forst- & Industrietechnik Scharf GmbH, Eggers Fahrzeugbau GmbH, Paul Nutzfahrzeuge GmbH, BICKEL-TEC GmbH and TITAN Spezialfahrzeugbau GmbH. They are all based in Germany. This results in short transport routes, rapid coordination, and efficient manufacturing processes within the CTT network.

The vehicles are initially produced in series at the Wörth plant. The individual customer-specific conversions and adaptations are then carried out by the CTT experts. Several thousand customized trucks leave the conversion workshops in Molsheim, Wörth, and at partner companies every year. Close cooperation with Daimler Truck's central development department ensures that recurring special solutions can also be incorporated into Mercedes-Benz Trucks' series production line in Wörth as required

Customized solutions from the "Would you like a little more?" category

The wide range of services extends from wheelbase shortening and lengthening to the installation of additional axles, frame reinforcements, and modifications to the cab,

right through to complex heavy-duty conversions. All vehicles meet the high-quality standards of Mercedes-Benz Trucks and can be serviced and repaired in authorized workshops. When responding to market inquiries from around the world, as many Mercedes-Benz Trucks series components as possible are used to preserve the character and characteristics of a truck with the star logo and to ensure the smoothest possible availability of spare parts.

For example, the CTT unit in Molsheim is currently working on a major order from Bundeswehr Fuhrpark Service GmbH. After the ordered Mercedes-Benz Arocs 6x6 trucks have been produced on the assembly line in Wörth am Rhein, CTT equips the vehicles with military-specific features.

CTT also meets the demand for particularly slim Mercedes-Benz Econic vehicles with a cab width of only 2.40 meters for Berlin's municipal waste management company. In addition, more than a hundred vehicles for Autobahn GmbH are currently being converted from 2-axle to 3-axle vehicles for higher payloads in Molsheim. CTT also supports the transformation to battery-electric drives by individually converting electric trucks.

One example of the cooperation between the locations was the Actros 8x4/4 Full-SLT at the end of 2023. After the series-production Actros rolled off the assembly line in Wörth, the original 3-axle vehicle was converted in Molsheim and at TITAN in Sulzbach into a 4-axle Full-SLT with two driven axles so that it could be used as a semi-trailer tractor for heavy-duty transport. To this end, an 8-ton leading axle was installed and a frame was mounted behind the cab to provide space for a 900-liter tank, air pressure tank, and a rear cooling system for cooling during fired operation and retarder operation. The retrofitted fifth wheel coupling and sliding device allow for efficient axle load distribution.

The Mercedes-Benz Arocs SLT 4463 AS 8x6 with a maximum trailer load of 1,000 tons for heavy-duty specialist Baumann was also manufactured in Molsheim and at one of the partners, Paul. At the CTT plant in Molsheim, the vehicle was fitted with a leading axle with start-up assistance via load relief control. In addition, the fifth wheel coupling, heavy-duty shifting device, and heavy-duty trailer couplings at the front and rear were retrofitted. Added to this were the SLT frame behind the cab with additional cooling system, a 900-liter fuel tank, and the hydraulic system for the trailer steering. The conversion team at Paul then replaced the 2.3-meter-wide StreamSpace cab with the 2.5-meter-wide BigSpace cab. The cab replacement meant that all interior fittings, such as the dashboard, bed, and drawers, had to be adapted. In order not to exceed the permissible total height of four meters, the front of the vehicle was lowered and a small engine tunnel was installed in the cab floor. In addition, Paul installed an additional tower with storage boxes behind the cab and mounted the ballast platform. In total, Paul installed or replaced approximately 9,500 parts.

In the case of the Mercedes-Benz Arocs 4763 8x6, for example, specific modifications were made for the Japanese market. Since a maximum height of 3.8 meters is specified in Japan, CTT in Molsheim developed a combination of the ClassicSpace 2.3 cab with a compact additional cooling tower on a chassis with a fourth axle for the first time and installed a heavy-duty coupling and mounting plate.

Article assets

Molsheim plant

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

The Key Here is Routine: Mercedes-Benz Special Truck Factory Delivers 300,000th Custom-made Vehicle

Truck with 1,000-ton towing capacity: Mercedes-Benz Trucks delivers special heavy-duty truck to customer

Market launch in Japan: Mercedes-Benz Trucks heavy-duty transporter Arocs and Actros models now available

Molsheim plant

Molsheim plant

Molsheim plant

Molsheim plant

Molsheim plant

Molsheim plant

Molsheim plant

Molsheim plant

Molsheim plant

Mercedes-Benz Arocs as a military logistics vehicle for BwFuhrparkService GmbH

Customization on wheels – Mercedes-Benz Custom Tailored Trucks celebrates its 25th anniversary

Lukas Hettmannsperger

Spokesperson Mercedes-Benz Special Trucks

lukas.hettmannsperger@daimlertruck.com

+49 170 3871112

Annika Pflüger

Spokesperson Mercedes-Benz Trucks Plants Wörth, Aksaray and Molsheim

annika.pflueger@daimlertruck.com

+49 176 30968626

Ulrike Burkhart

Spokesperson Mercedes-Benz Trucks Product, Service & eTruck

ulrike.burkhart@daimlertruck.com

+49 160 861 3757