At Daimler Truck, we are fully commited to sustainability not only in the development of new emission-free vehicles, but also in the production of our products. We are aware of this responsibility and are facing up to the challenge. For this reason, we are working to make our production as environmentally friendly as possible and to reduce CO2e emissions and resource consumption.

Green Production

Our ambition

We want to realize CO2e neutrality* on the balance sheet at our production sites in the US, Japan and India by 2025 - globally we strive for CO2e neutrality by 2039.

To drive the transformation of our industry forward quickly, we are working intensively to achieve CO₂e neutral sites around the world.

*among other things through the procurement of CO₂e neutral electricity from solar, wind and hydropower and through procurement of certificates

Our path

To achieve our ambition and to expand climate protection and resource conservation in production, a few years ago we launched the "green production initiative”. This initiative aims to reduce CO2e-emissions, increase the use of renewable energy, improve energy and water efficiency, and reduce waste at our global production sites.

-

CO₂e neutral global production

In this context, we are pursuing a four-pronged strategy on our path to CO2e neutral global production:

- Improved energy efficiency

As part of the “Green Production Initiative”, we will continuously reduce energy consumption at our production sites by around 590 GWh by 2030 (compared to 2013 and 2014). - Purchasing of renewable energy

We are focusing on renewable energy in our factories. Here we are continuously evaluating the regional energy markets so that the green power supply can be expanded at all of our locations. Since the beginning of 2022, the majority of our production sites in Europe have been supplied with green electricity from wind turbines, photovoltaic systems, and hydroelectric plants. This also applies to plants in the USA and Japan, which have also been sourcing electricity from renewable sources since 2023. By 2025, we also aim to supply 100 % green power to all our production sites in the USA, Japan, and India. All other in-house production sites are set to follow by 2030 at the latest. - Company production of renewable energy

In addition to purchasing green electricity, we are continuously driving forward the self-generation of energy at our production sites. Around 20.6 MWp of photovoltaic modules have been installed worldwide, generating around 25,700 MWh of electricity per year (as of the end of 2023). Further photovoltaic systems are planned at numerous locations – including Turkey, South Africa, Mexico, and Japan. Daimler Truck, EnBW and the city of Woerth am Rhein have founded the joint venture "WärmeWerk Woerth GmbH" in 2023. This is intended to explore the possibilities of a climate-neutral energy supply for the Mercedes-Benz plant in Woerth and the town of Woerth am Rhein using geothermal energy. The aim is to determine the usability of geothermal energy and, if necessary, to build and operate a geothermal plant to generate heat at the Woerth site. If the federal funding applied for is approval, the geothermal heating plant could be built and connected to the heating network from 2027 as things stand today, meaning that it could be commissioned in 2028. - CO2e compensation in transition phase for remaining emissions

We are compensating our currently remaining CO2e emissions with qualified climate protection certificates (gold standard). At Daimler Truck, we consider compensation to be a means of transitioning to a CO2e neutral production. At the same time, we are working on further technical means to reduce emissions at the production sites themselves. Our sustainable business strategy aims to avoid emissions in the future as much as possible.

- Improved energy efficiency

-

Waste Reduction

Reducing waste is also an essential part of using our resources sparingly. To achieve this, we are working harder to reduce the consumption of raw materials and materials at our sites. We are minimizing waste such as offcuts, sand, filter materials and sludge through new or optimized production processes, and closing off material cycles wherever possible. We are also trying to reduce our packaging materials from parts transport.

In principle, we strive to dispose of our waste primarily through recycling processes rather than disposal processes. The disposal methods are regularly checked by our experts for optimization possibilities. This enables us to direct waste streams to a higher-quality recycling process.

-

Environmental Management Systems

At our production sites, we implement advanced environmental management systems in accordance with EMAS and/or ISO 14001, which are validated and recertified every three years. In addition, we have implemented energy management systems in accordance with ISO 50001 at many locations since 2012. These standards are an integral part of our corporate strategy, and the effectiveness of the systems is regularly reviewed and confirmed by external auditors.

Since 1999, we have applied the ‘Environmental Due Diligence Method’ throughout the company to ensure that our corporate standards are implemented at all levels. This method enables us to identify, assess and prevent potential risks of environmental pollution at an early stage. In this way, we ensure a high level of environmental standards worldwide. All relevant production sites are assessed every five years in a standardised review process in order to minimise potential environmental risks. Additionally, we review the implementation of our recommendations for preventing environmental impacts at the individual sites on an annual basis.

As part of this environmental due diligence method, around 20 % of our 50 relevant locations are audited and assessed each year.

-

Protecting biodiversity

In addition to our extensive activities in the areas of climate protection, emission control, water management and soil protection, we are also specifically committed to preserving biodiversity at our production sites. We promote the natural design of green spaces and support projects that contribute to the promotion of biodiversity. This is achieved through internal recommendations, guidelines, and collaboration in working groups that support projects from the planning phase to implementation.

In addition, we work closely with various nature conservation organisations that advise, support and assist us in our efforts related to animal and plant protection, as well as and in the near-natural design of green spaces.

To specifically assess the biological value of the areas at our sites and develop customised concepts for their further development, we have created an internal Biodiversity Index (BIX).

This index was initially introduced at our German locations and will applied to our international locations in the future.

Another key aspect of our commitment is raising awareness among our employees about biodiversity. We actively involve them in projects and measures to protect biodiversity through initiatives and campaigns.

Our progress so far

- Since 2022 we achieved CO₂e neutrality in production for our sites in Europe and at other locations on the balance sheet – through among other things the procurement of CO₂e neutral electricity from solar, wind and hydropower and the procurement of certificates.

- We are working consistently to further reduce CO2e emissions and resource consumption in our production. In 2024, we have reduced our CO2e emissions in production by 13.8% compared to the previous year – and by 35.3% since 2021 – through the use of renewable energies and efficiency measures, among other things.

- Worldwide, we have already installed around 40.6 MWp of photovoltaic modules at our production sites. In this way, we are constantly driving forward the use of renewable energy at the production sites and generated 35.7 GWh of electricity from solar radiation in 2024. At our site in South Africa, we built a 13.5 MWp ground-mounted photovoltaic system last year together with an investor. This allows us to avoid around 20,000 tons of CO₂e annually.

- Implementation of numerous efficiency measures as part of the "green production initiative".

- 92% of our relevant sites (production plants, development, and test track sites) are ISO 14.001 certified.

Our next steps

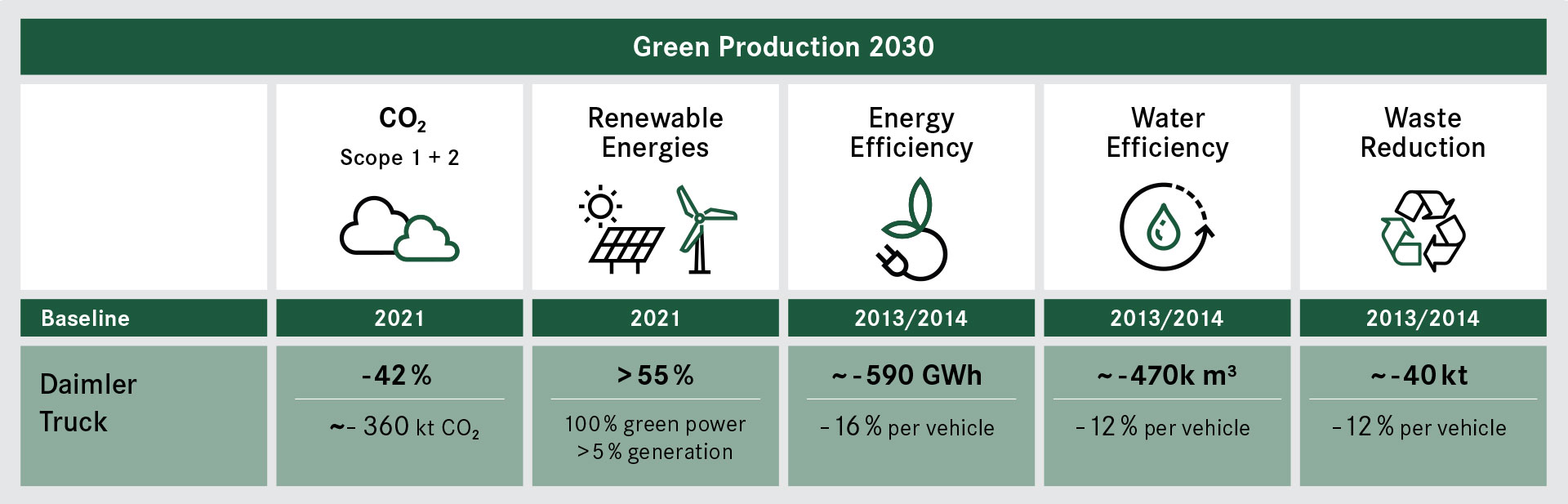

As part of our “green production initiative”, we aim to achieve the following objectives by 2030:

- We aim to reduce production-related CO2e emissions by 42% compared to the emission levels in 2021.

- At least 55% of energy is expected to come from renewable energy sources.

- Our goal is to reduce energy consumption by around 590 GWh**.

- We aim to reduce water use by around 470,000 m3**.

- We want to reduce waste by around 40,000 tons**.

** based on the average value for the years 2013 and 2014